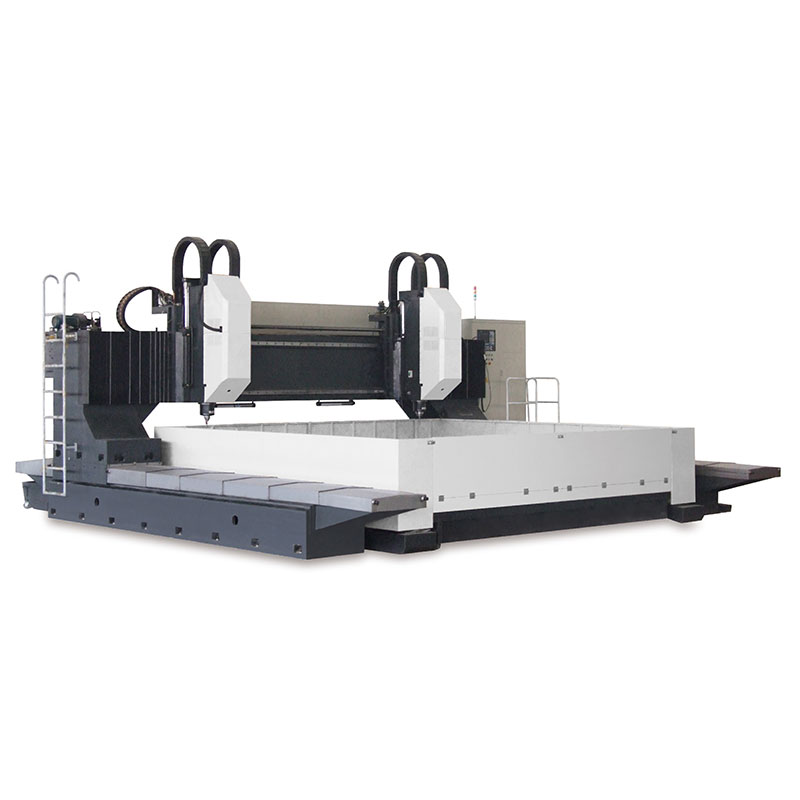

PCL Control CNC Beam Line

PCL Control CNC Beam Line

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Delivery Time: 30 Days

Send Inquiry

PCL Control CNC Beam Line

Basic Info

Model No.: BD

Application: Metal

Numerical Control: CNC/MNC

Processing Precision: ±0.05mm

Certification: GS, SGS, CE, RoHS, ISO 9001

Condition: New

Function: H Beam Drilling

Max. H Beam Size: 1250*600

Drilling Hole: 12-40

No. Of Drilling Spindle: 3pcs

Feeding Speed: 0-8m/min

Spindle Speed: 0-4000r/min

Additional Info

Packaging: Wooden Pallet

Productivity: 20set

Brand: SF

Transportation: Ocean

Place of Origin: China

Certificate: ISO9001

Port: Qingdao Port

Product Description

Beam Drill Lines is suitable for drilling three sides of H-beam and U-channel in steel structure industry.

Feature

1.Three power heads can work simultaneously or independently high-speed drilling,chamfering,tapping and other

processes.

2.Both vertical and horizontal with hydraulic clamping device.

3.Three power heads with an automatic tool changer.

4.Three axes can achieve high speed lettering lining.

Technology parameter

| Drill Range | H*W | Max(mm) | 1250×600 |

| Min(mm) | 150×75 | ||

| Thickness(mm) | ≤80 | ||

| Max Length(m) | 15(can be customized) | ||

| Min length(m) | Auto mode 3000 | ||

| Manual mode 690-3000 | |||

| Axis | Drill dia. | Middle axis (mm) | φ12~φ33.5 |

| Side axis (mm) | φ12~φ26.5 | ||

| Qty. of drill axis(pcs) | 3 pcs | ||

| Drill speed (r/min) | 180~560(Frequency) | ||

| Taper of axis | Mohs 4 | ||

| Feeding speed (mm/min) | 0-200(Feeding car) 0-150(Feeding Roller) | ||

| Axial stroke | Middle axis(mm) | 240 | |

| Side axis (mm) | 140 | ||

| Move distance | In workpiece length direc ion (mm) | 520 | |

| Side axis in up and down direction (mm) | 35-570 | ||

| Middle axis in workpiece width direction (mm) | 45-1160 | ||

| Cooling | Cooling | Compressed air + cutting fluid | |

| Air pressure(mpa) | ≥0.5 | ||

| Accuracy | Error of adjacent holes in hole group (mm) | ±0.5 | |

| Ac uracy of adjacent feeding distance within(mm) |

1 |

||

| Motor power | Spindle axis motor(KW) | 4x3 | |

| Middle axis X servo motor(KW) | 0.85 | ||

| Middle axis Z servo motor(KW) | 1.3 | ||

| Side axis X servo motor(KW) | 0.85x2 | ||

| Side axis Y servo motor(KW) | 1.3x2 | ||

| Dragging Plate Motor(KW) | 0.85 | ||

| Dimension(L×W×H)(m) | 4.8×2.4×3.3 | ||

| Weight(㎏) | About 7500 | ||

MAIN COMPONENT LIST

| No. | Item | Model | Qty. | Brand |

| 1 | Linear guide | HGH35 | 6 | HIWIN |

| 2 | Ball screw | R32-5T3 | 3 | HIWIN |

| 3 | Pump and motor group | 3KW | 1 | YUKEN |

| 4 | Servo motor | 6 | Japan Yaskawa | |

| 5 | Upper computer | Lenovo | ||

| 6 | Sensor | PS | AUTONICS | |

| 7 | Flow control valve | QC-06/1 | 3 | YUKEN |

| 8 | Magnetic valve | WE6EA50/AG20 | 5 | AUTONICS |

| 9 | one-way valve | Z2S10A2 | 2 | AUTONICS |

| 11 | Diffuse switch | QS18VP6DB | 2 | Schneider |

OPTION FOR FEEDING SYSTEM

1. CNC feeding car:

1.1 Automatic stop and alarm function, improve the reliability and safety of the workpiece conveying process

1.2 Simple structure, easy to install

1.3 Auto length

2. Feeding roller:

1.1 Low cost

1.2 Strong continuous productivity

1.3 Auto length