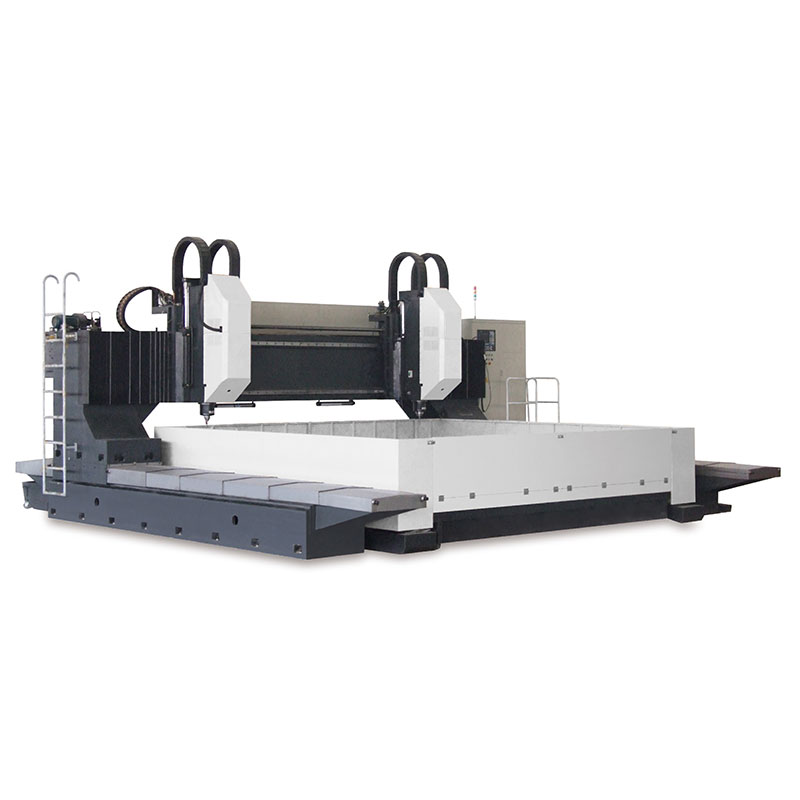

Double Spindle CNC Plate Processing Machine

Double Spindle CNC Plate Processing Machine

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

Delivery Time: 35 Days

Send Inquiry

Double Spindle CNC Plate Processing Machine

Basic Info

Model No.: BD

status: New

Types of: Vertical

Processing capacity: Heavy Duty

Spindle bore (mm): 40

Number of spindles: Twin

Number of axes: 3

Positioning accuracy (mm): ±0.002

Repeat positioning accuracy (mm): ±0.002

place of origin: China

CNC system: FANUC

Out-of-warranty service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Additional Info

Packaging: Wooden Pallet

Productivity: 30set

Brand: SF

Transportation: Ocean

Place of Origin: China

Certificate: ISO9001

Port: Qingdao Port

Product Description

CNC high speed drilling machine is drilling steel plate machine , drilling steel flange machine.

This machine is suit for drilling, milling,chambering, chamfering metal sheet.

This machine has high working efferency, especially suitable for multispecies and small batch workpiece processing.

Feature

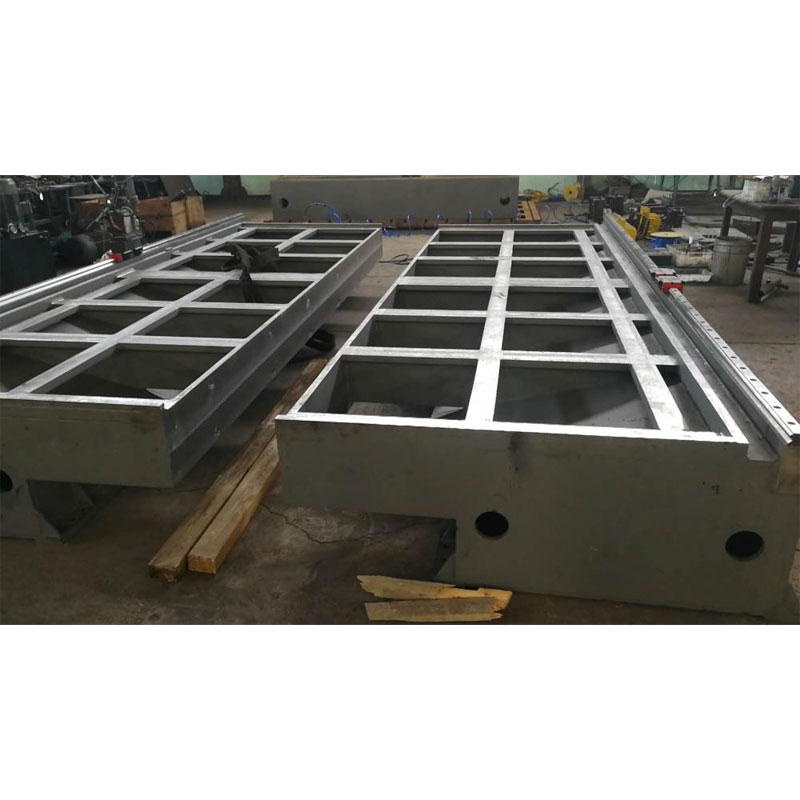

1. The bed is made of high quality gray cast iron with stable performance and no deformation.

2. Has four working area, which can drill and unloading workpiece at the same time,

3. Equipped with one two set of high capacity linear guide, AC servo motor, ballscrew and synchronous belt at both sides of machine bed to ensure the moving accuracy of gantry bracket.

4. The power head is controlled by hydraulic sensing system to automatically perform fast forward, work-in, fast-return conversions, so no need to set the driller length and workpiece thickness by manual.

5.The main spindle gear reducer are imported from Germany and has high working performance.

6. Electric system is controled by siemens to ensure the high working accuracy and good working quality.

7. Equipped with Network port, it’s more convenient to detect, repair and control machine through network

8. It is equipped with monitor function. When has fault, detailed cause and solution will be displayed on the screen.

◆Technology parameter

| Model | PHD1616 | PHD2016 | PHD2020 | |

| Processing size | LxW(mm) | 1600x1600 | 2000x1600 | 2000x2000 |

| Thickness() | 15-100 mm | |||

| Drilling spindle | Qty. of spindle | 1 | ||

| Model of spindle | BT40 | |||

| Speed of spindle | 30-4500 r/min | |||

| Feeding stroke | 260 mm(Servo feeding) | |||

| Tapping diameter | M20 mm | |||

| Clamping mode | Manual | |||

| Power of motor | Spindle motor | 7.5 /11 KW(Servo motor) | ||

| X-axis | 2×2.3 KW | |||

| Y- axis | 2.3 KW | |||

| Z- axis | 2.3 KW(with brake) | |||

| Precision of positioning | 0.1 mm | |||

| Precision of repeating positioning | 0.08 mm | |||

| Control mode | CNC system+ host computer | |||

| Weight of machine | 5.5 T | 6.6 T | 7.2 T | |

| Dimension | 3800x2050x2750 | 4200x2450x2750 | 4200x2850x2750 | |

| Optional- Tool magazine | 6units of Straight tools | |||

| Optional- automatic clamp | 12 units of hydraulic clamper | |||