Industry News

The operation method of the film pressing machine

The operation method of the film pressing machine is as follows: 1 Before starting the machine, it is necessary to check whether the fastening bolts of the equipment are loose, clean all parts of the laminating machine with thinning water, and adjust the glue again later. Do not store any sundri......

Read MoreHow to maintain the polishing machine?

Polishing machine maintenance: 1. Check the electrical circuit regularly, and replace it immediately if it is damaged. 2. Check the parts of the equipment regularly and reinforce them immediately if they are loose. 3.Add lubricating oil to the oil filling hole regularly. 4.Before work to try the boo......

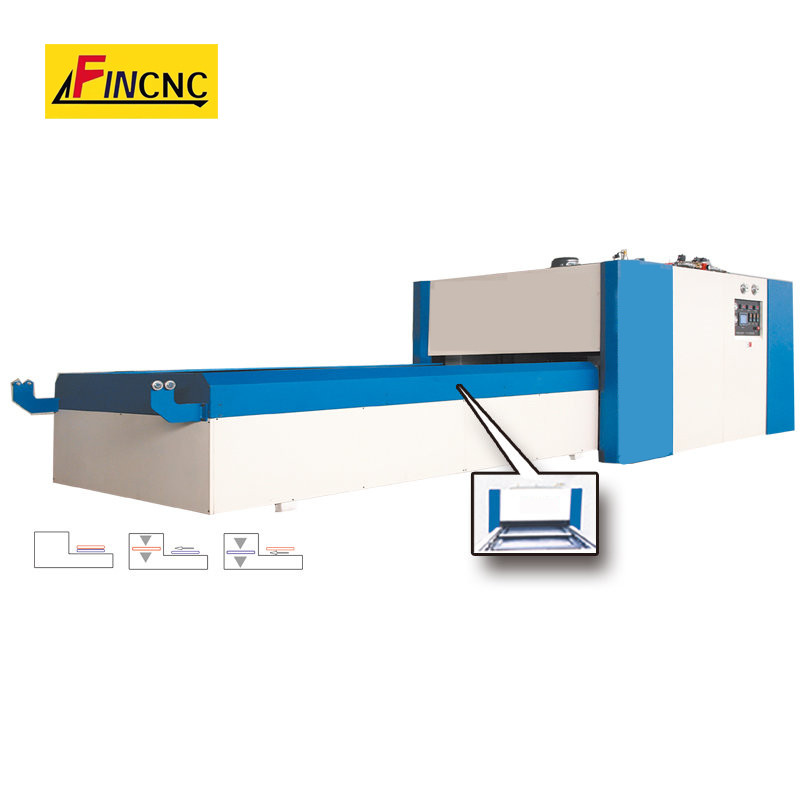

Read MoreThe working principle of vacuum laminator

When the machine is powered on, the upper and lower heating plates of the machine start to heat up, and the vacuum system starts to work, so that the space in the working area is close to the vacuum state, to ensure that all the air between the pressed material and the material is discharged.

Read MoreApplication range of multifunctional laminating machine keeping pace with the times

The multi-functional laminating machine is to coat plastic film with adhesive and press it with paper as the substrate. After being pressurized by rubber drum and heating drum, it forms a product of paper plastic integration.

Read MoreInspection and analysis of automatic laminating machine before use

The full-automatic laminating machine is to regularly check whether there is rubber and oil dirt on the rubber roller, and wipe the glue mark and dust on the roller in time to ensure that the appearance of the two rollers is black.

Read MoreWhat are the characteristics of automatic laminating machine equipment?

The automatic laminating machine requires high precision in its work, especially the surface precision and shopping degree of each roller. Once there is a little speckled, cracked, scratched, covered point, or slightly circuitous deformation. Will affect the processing quality of products, even can......

Read More