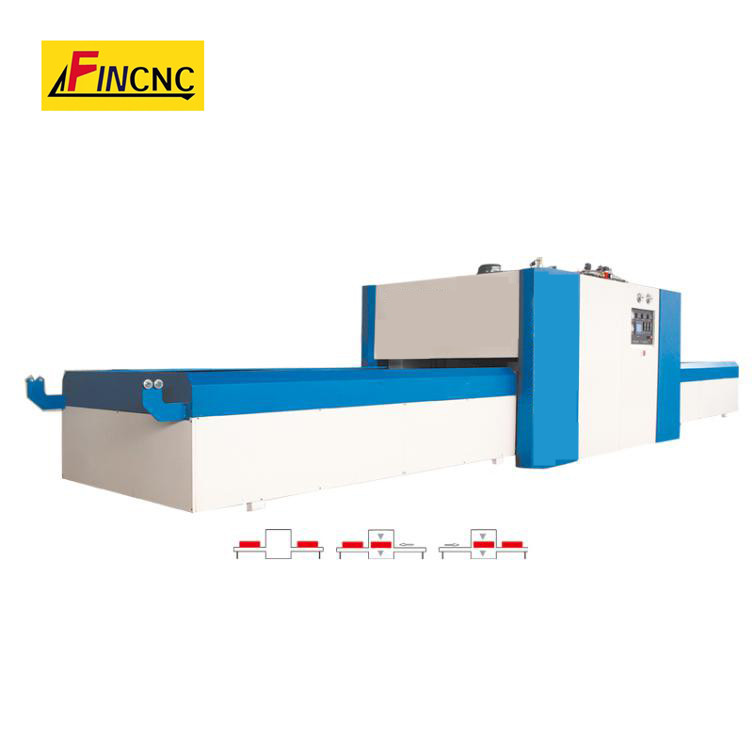

Woodworking Vacuum Membrane Press Machine

Excellent adhesive strength,clear surface for Woodworking vacuum membrane press machine.Ten years factory,Customized Product. Shaped surfaces covering,Quick delivery.Shandong EN FIN CNC Machinery Co., Ltd.

Send Inquiry

1.Product Introduction of the Woodworking vacuum membrane press machine

This Woodworking vacuum membrane press machine is fully automatic vacuum coating equipment, can be a variety of high-grade PVC , transfer film, leather furniture surface coating of paste.The high degree of automation and simple operation, processing time, working temperature, vacuum value , all automatic control, to ensure product quality, improve production efficiency.

2.Product Parameter (Specification) of the Woodworking vacuum membrane press machine

|

Working surface |

2580×1270×50mm |

|

Pressure |

Positive Pressure≤0.5Mpa Vacuum≥-0.095Mpa |

|

Dimension |

10080×2140×2150mm |

|

Power |

45kW |

|

Weight |

13T |

|

Voltage |

380V 50HZ (Can order) |

|

Warranty |

1 year |

3.Product Feature And Application of the Woodworking vacuum membrane press machine

1) The Woodworking vacuum membrane press machine is PLC touch screen,operationis optional simple and precise .

2) Double working tables,save time and efficient.

3) The machine have positive and negative.

4) This machine is suitable for covering PVC film on the surfaces of all kinds of plate type furniture, sound boxes and ornamental materials etc.

5)Particularly it is used to covering on concave and convex line and various shape edge surface.

6)It is the ideal equipment in interior design.

7)This machine can be used to paste high gloss PVC,paper and heating transfer printing on furniture, cabinets, speakers, relief doors, decoration panels for walls and other abnormal decoration shapes.

4.Product Details of the Woodworking vacuum membrane press machine

1)Machine structure:The Woodworking vacuum membrane press machine frame board all choose whole steel plate,stable and durable。

2)Electric parts:All the key components of electrical system adopts Schneider and Omron brandlong service time.

3)Slicon sheet:when the Woodworking vacuum membrane press machine make complete membrane,silicone board only play the role of warm.positive pressure working without silicone board but small piece membrane.

4)Vacuum pump:The vacuum pump performance could match the Europe brand,and its main parameter have over the Germany products .the pump head adopts low alloy cast iron ,higher abrasion resistance and corrosion resistance.

5)Control system:Operation system PLC, control interface originally from Japan with advanced technology and highly automatic.

6)Automatic cutting The Woodworking vacuum membrane press machine with automatic cutting can cut PVC easy.

5.Product Qualification of the Woodworking vacuum membrane press machine

The Woodworking vacuum membrane press machine with CE certificate.

6.Deliver,Shipping And Serving of the Woodworking vacuum membrane press machine

The standard packing of the Woodworking vacuum membrane press machine is foam,can order wooden box .

7.FAQ

Q1.Warranty

12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

TT 30% down payment, 70% before shipment.

Q3. Delivery Time

15-30 working days from the receipt of the down payment.

Q4. Technical Support

Every machine is assigned by a specialist. The response is available within troubleshoot and solve problems on line.

Q5.Demo and Testing

In order to built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

Q6.Door-to-door service

We can offer door-to-door service if you need for payment.