Angle Steel Drilling Machine

Angle Steel Drilling Machine

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Min. Order: 1 Bag/Bags

Delivery Time: 30 Days

Send Inquiry

Angle Steel Drilling Machine

Basic Info

Model No.: CAD

Application: Metal

Process Usage: CNC Non-Conventional Machine Tools

Movement Method: Linear Control

Control Method: Closed-Loop Control

Numerical Control: CNC/MNC

Processing Precision: ±0.05mm

Performance Classification: High-End CNC Machine Tools

Certification: GS, SGS, CE, RoHS, ISO 9001

Condition: New

Max Angle Size: L250*250*32

Typing Force: 1300KN

Max Length Of Blank Workpiece: 14m

Max Length Of Finished Workpiece: 14m

Die No.: 3

CNC Axis: 3

Qty. Of Typing Group: 1

Spindle Speed: 180-560r/min

Dia. Of Drilling Hole: 40

Additional Info

Packaging: Wooden Package

Productivity: 30set

Brand: SF

Transportation: Ocean

Place of Origin: China

Certificate: ISO9001

Port: Qingdao Port

Product Description

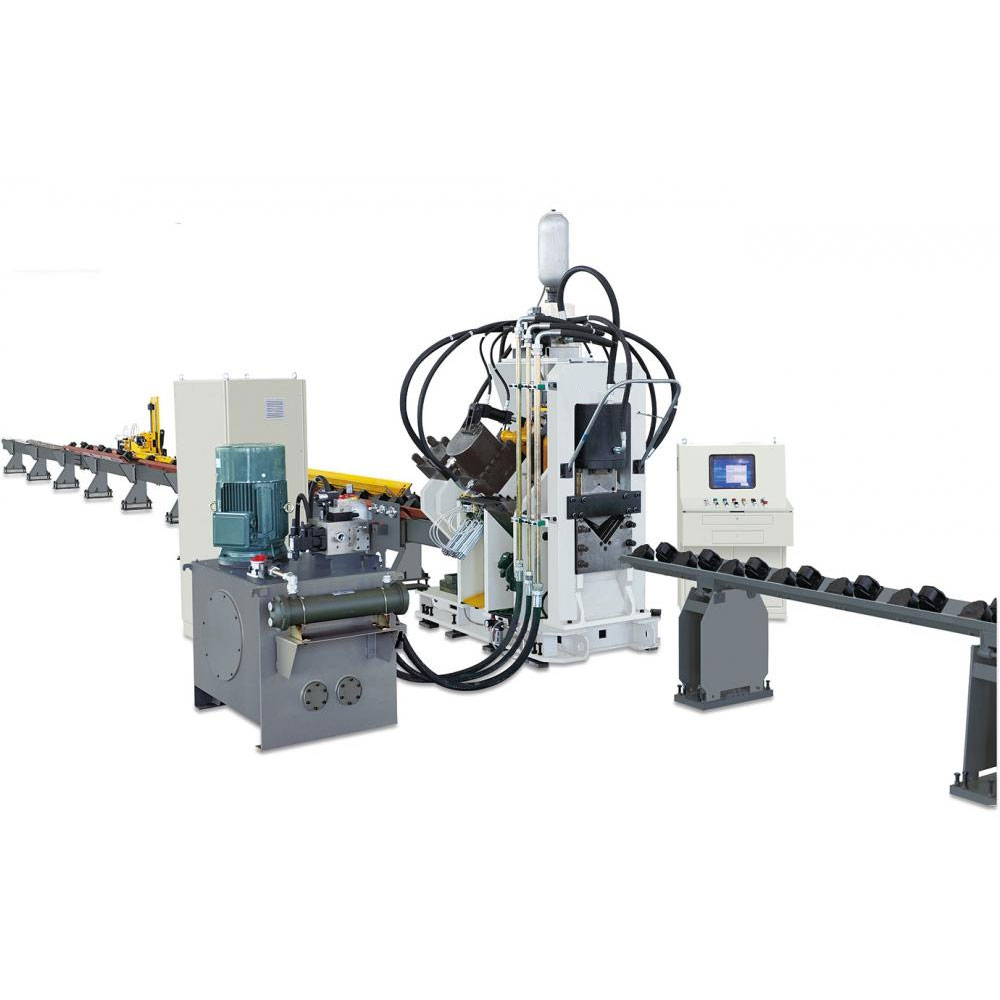

Angle drilling line is suitable for power tower,communication,steel structure bar marking and drilling.

Feature

1.This machine adopt CNC technology, servo motor feed makes positioning accurate high efficiency, stable working accuracy.

2.The CNC system has the function of real-time monitoring fault self-diagnosis function and abnormal alarm function abnormal operation will automatically stop.

3. Liquidgaselectric parts all import

4.Chinese/English interface can display the graphics of work-piece and operate easily.

5.Print and drill are automatically, finished production with pneumatic flip unloading. Reduce the labor intensity greatly.

6.We can obtain the computer editing process through the CNC system for processing.

7.It has the function of high speed drilling, the top speed of the drilling spindle up to 3500r/min.

8.It has two set of six independent axis, those axis 90layout on the main frame Servo motor drive can drill in any position

9.Adopt the worlds most advanced short-hole drill, the surface of processing highly polished, the hole size is accurate, work efficiency is high

Technology parameter

| MATERIAL of ANGLE STEEL | ||

| Min. SECTION TO BE DRILLING | MM | 130 X 130 X 12 |

| Max.SECTION TO BE DRILLING | MM | 250 X 250 X 36 |

| Max.Length Of Piece | Mtrs | 14 |

| DRILLING PARAMETER | ||

| Mode of operation | manual/ cnc | both |

| Method of coolant Injection | Inner / Outer | both |

| Min. Dia. Of Hole to be drilling | MM | 12 |

| Max.. Dia. Of Hole to be drilling | MM | 32 |

| Min. Back mark | MM | 30 |

| Max. No. of drilling tool at each sides | no | 3 |

| Max. Spindle Speed | RPM | 6000 |

| Max. power head feeding speed | m/min | 14 |

| MARKING PARAMETER | ||

| Type of Marking Unit | Cassette | Cassettes |

| No of character Group (cassettes) | no | 4 |

| No Of character in Each cassettes | no | 15 |

| Size of character | mm(W x H x L) | 12x20x30 |

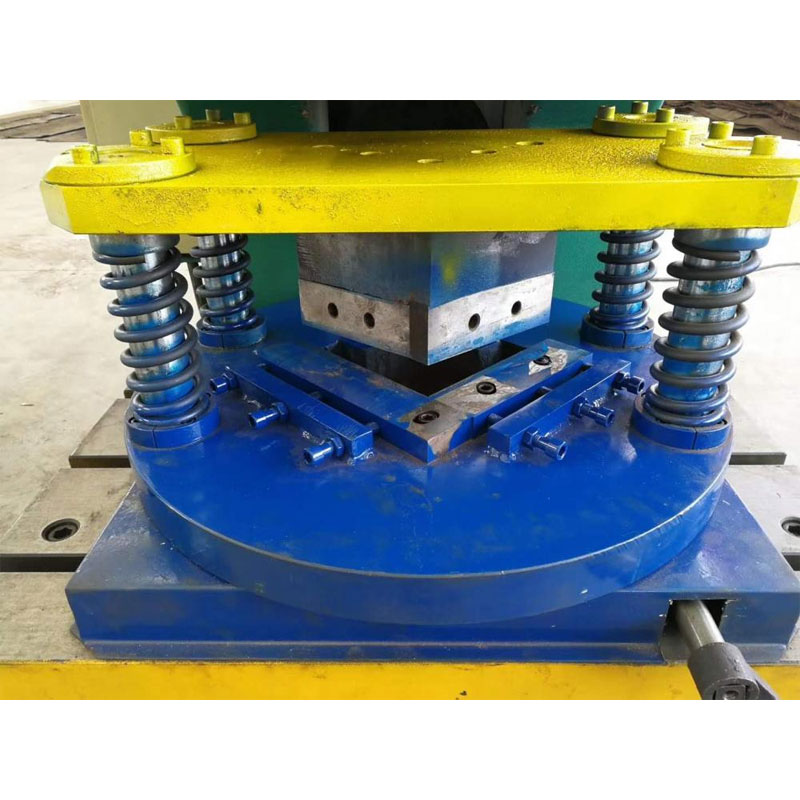

| PINCHER PARAMETER | ||

| X carriage runner |

|

Linear Guide |

| Max angle steel feeding speed | m/min | 40 |

| OUTFEED TABLE PARAMETER | ||

| Length of Outfeed table | Mtrs. | 12 |

| System of operation | Pneumatic/Hyd. | Hyd |

| Mode of operation | Auto / Manual | Auto / Manual |

| ELECTRICAL PANEL PARAMETER | ||

| Supply system | 3-phase,415 VAC, 0 Hz | |

| Provision for cooling | Inbuilt AC Unit | |

| CNC axis No. | Pcs | 9 |

| Dimension | m | 30×8.9×2.5 |

| Total power | kW | 109.7 |

| Weight | Kg | 30000 |

| Magnetic valve | Japan SMC |

| Cylinder | Japan SMC |

| Magnetic switch | Japan SMC |

| Main parts for hydraulic | Italy-ATOS |

| PLC | Japan Mitsubishi |

| Servo motor | Japan Panasonic |

| Servo amplifier | Japan Panasonic |

| Encoder | Koyo |

| Computer | Lenvo |